|

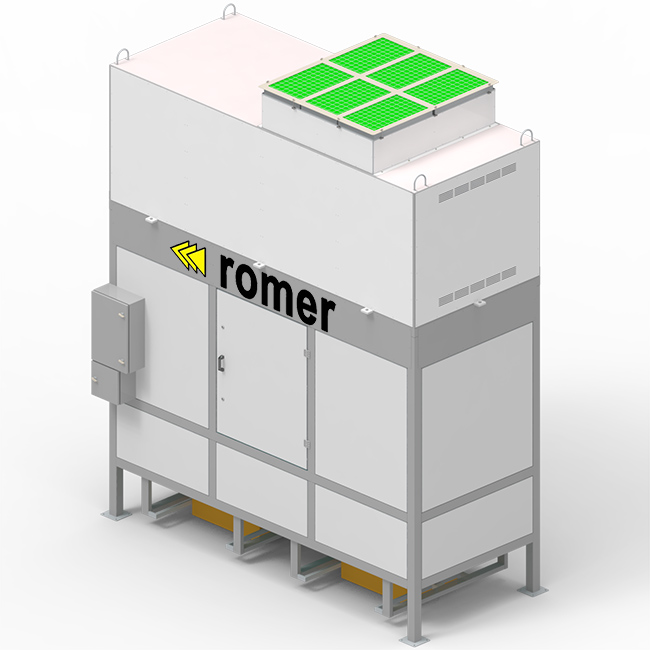

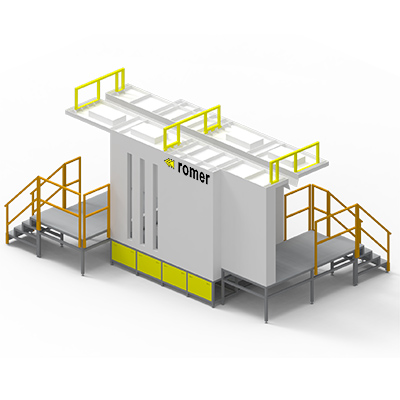

Touch computer control |

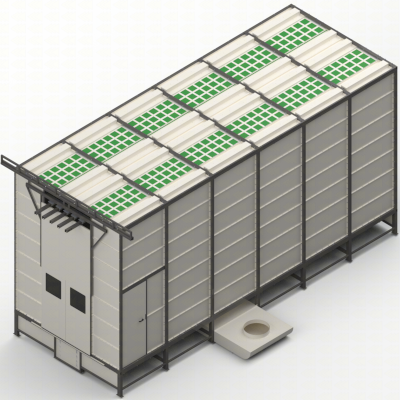

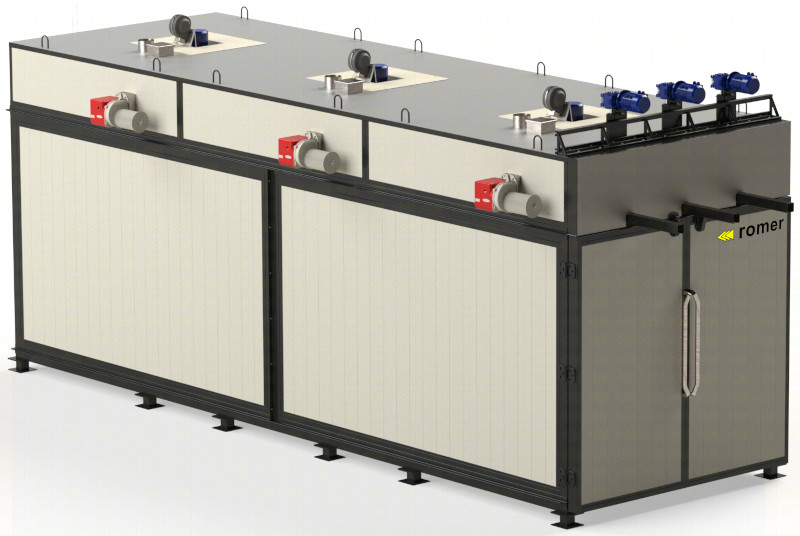

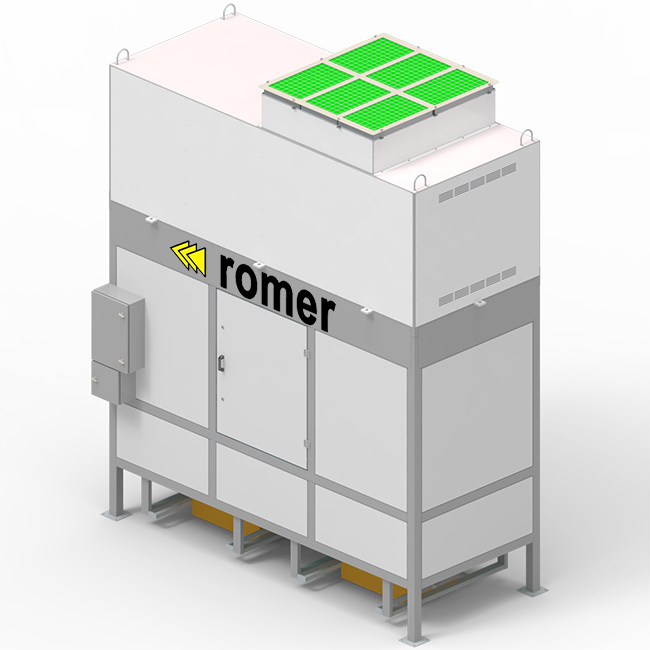

Thick insulation 240-300mm |

|

|

|

|

|

|

|

Swiss heaters |

|

|

Forced circulation with both walls and floor |

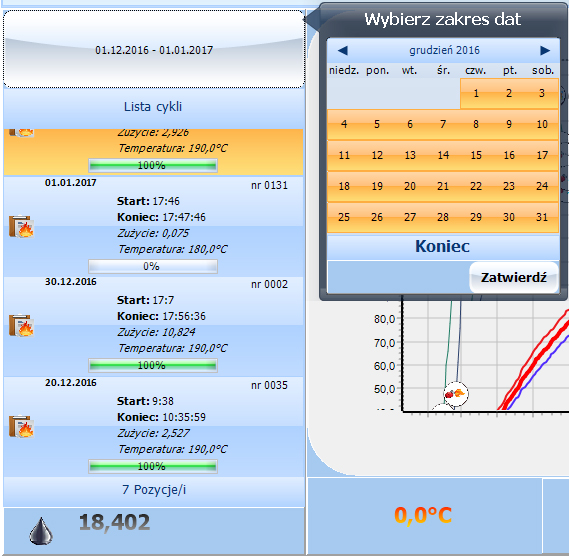

2 channel USB recorder + full history |

| Series | SL Series | SL Series | SW Series | SW Series | SW Series |

| Power | Electricity | Electricity | Oil | NG / LPG | NG |

| Forced air circulation | ✔ | ✔ | ✔ | ✔ | ✔ |

| Two-channel USB temperature recorder | ✔ | ✔ | ✔ | ✔ | ✔ |

| Number of temperature sensors | 1 | MTS 2+ | MTS 3+ | MTS 3+ | MTS 2+ |

| Wall insulation thickness (mm) | 80 | 240 | 240 | 240 | 240 |

| Ceiling insulation thickness (mm) | 80 | 300 | 460 | 460 | 460 |

| Number of programs | 1 | 20 | 20 | 20 | 20 |

| Max. Number of steps in the program | 1 | 10 | 10 | 10 | 10 |

| Average heating time up to 180 ° C | 40min | 35min | 25min | 25min | 20min |

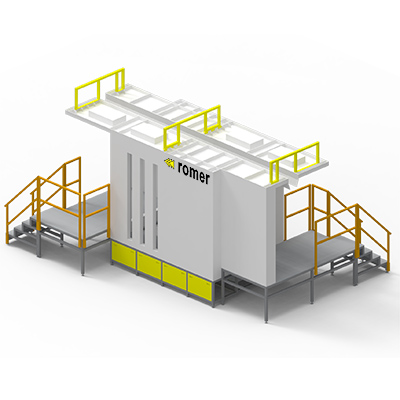

| Number of door leaves | 1 | 2 | 2 | 2 | 2 |

| Diagnostics / update via the internet | ✖ | ✔ | ✔ | ✔ | ✔ |

| Media consumption meter | ✖ | ✔ | ✔ | ✔ | ✔ |

| Stainless steel ceiling elements | ✖ | ✖ | ✔ | ✔ | ✖ |

| Direct heating | ✖ | ✖ | ✖ | ✖ | ✔ |

| Explosionproof closures | ✔ | ✔ | ✔ | ✔ | ✔ |

| Silicone door seal | ✔ | ✔ | ✔ | ✔ | ✔ |

| Price group | 1/2 | 2/5 | 4/5 | 5/5 | 3/5 |

Video

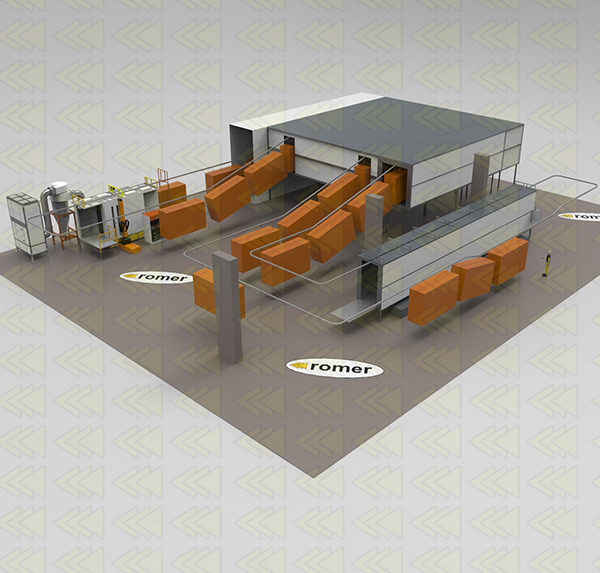

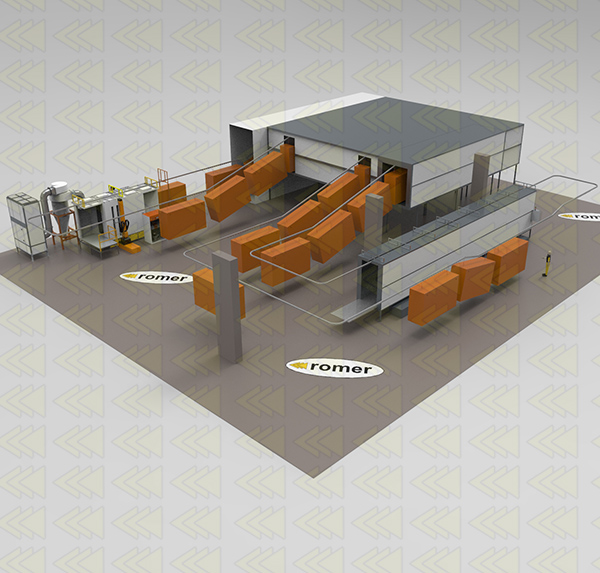

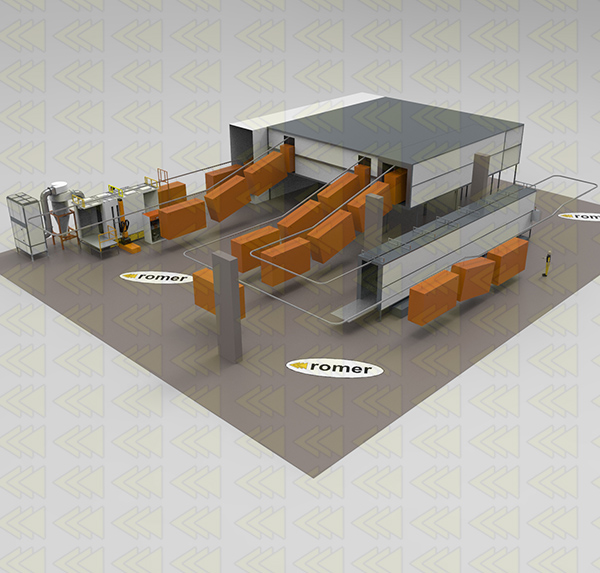

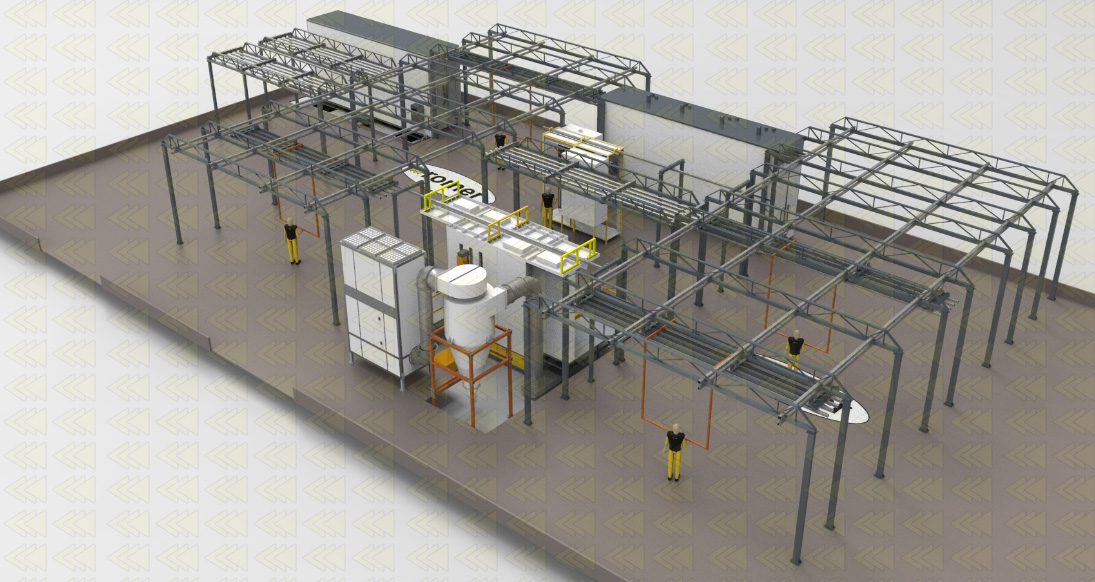

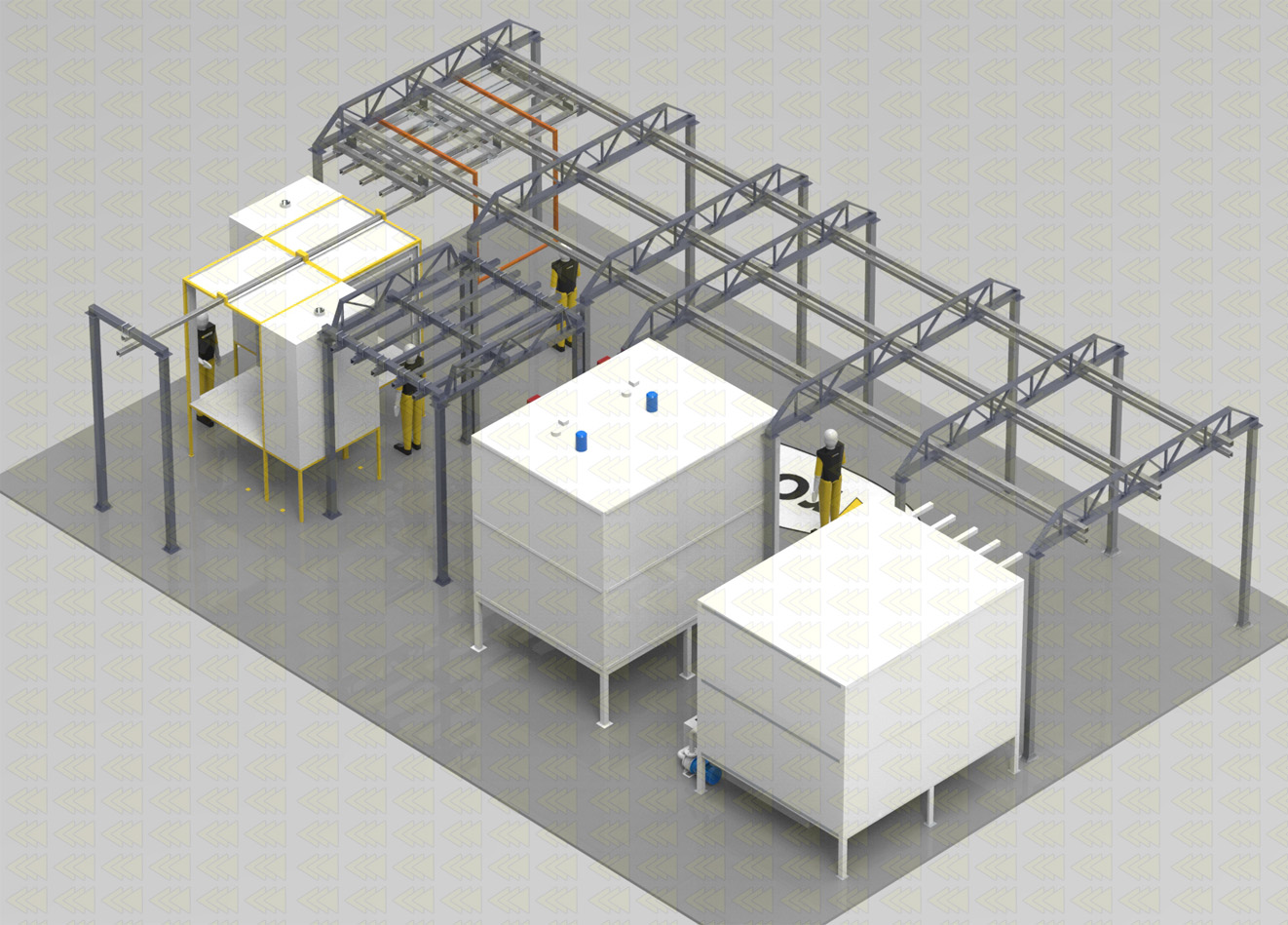

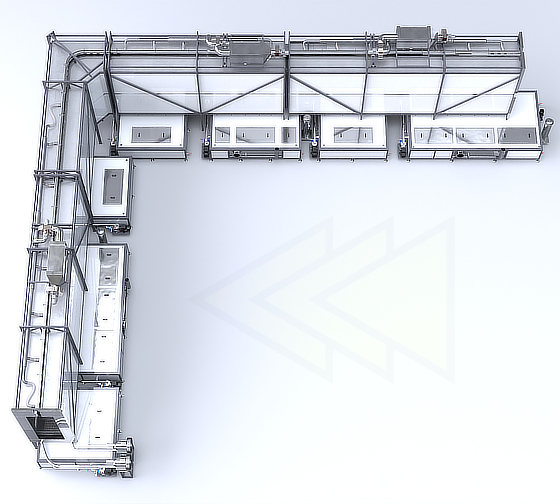

Automation

Enter the 21st century with our solutions

|

Automatic entry of slats

option |

| Watch the video - how it works. |

|

Automatic door opening

option |

|

|

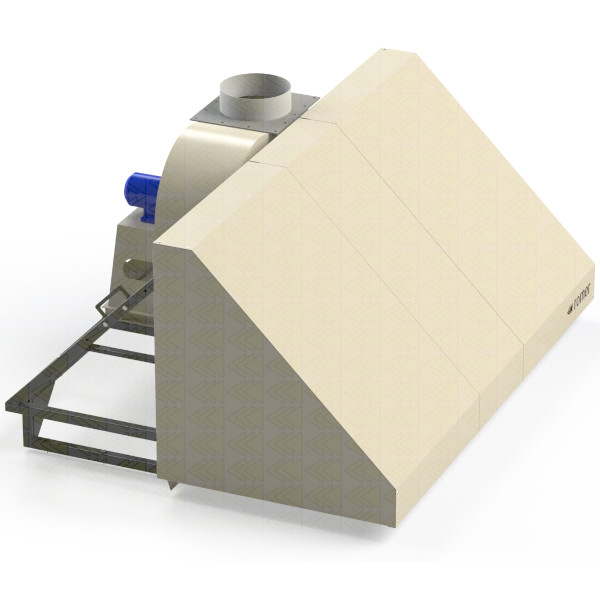

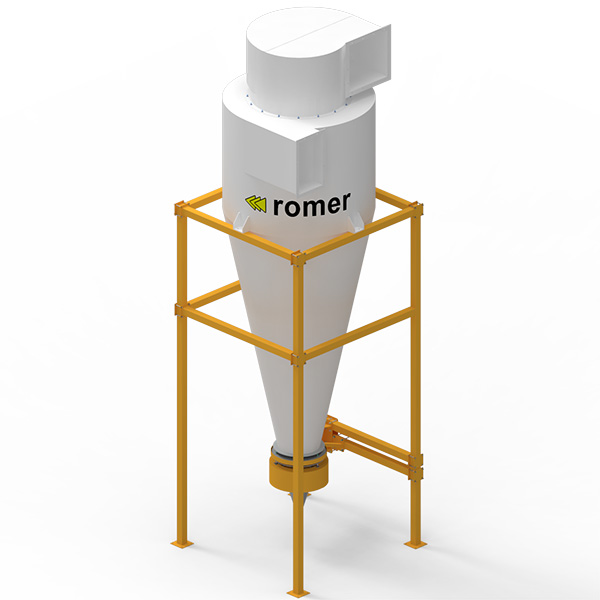

Automatic programmable hood

option |

Comfort

Comfort of use thanks to which work becomes pleasant

|

7" touch panel |

|

Memory of 20 programs of 10 events |

|

|

Information on electricity consumption |

|

USB |

New

|

|

New

|

Start baking automatically at 6am |

Developed by professionals, for professionals

|

Automatic smoke exhaust chimney |

|

Minute forecast until end |

|

|

Self-closing doors |

|

Heat hood

option |

|

Flexibility

Solutions worth investing in

|

Furnace division (Guard)

option |

|

2in1, i.e. drying with firing in a split kiln

option |

|

|

Airing the oven chamber

option |

ThPID system

Unique systems to ensure the highest firing quality

ThPID

What is the ThPID system?

The ThPID system was created to eliminate the effect of inertia called hysteresis.

The standard solution is based on a system that heats with constant power on/off.

ThPID

is a system in which, by means of voltage regulation, after reaching the set temperature, the heating power is selected that is currently needed - minimizing the effect of temperature fluctuations.

The ThPID system additionally allows you to cut the heating power of the furnace to a preset percentage value, eg in the absence of power at a given moment.

|

ROMER

|

Other |

|

|

MTS system

MTS system

What is the

MTS system?

The

MTS system was created to provide a real temperature reading of the oven chamber.

The standard measurement is based on a single temperature measurement which is often misleading.

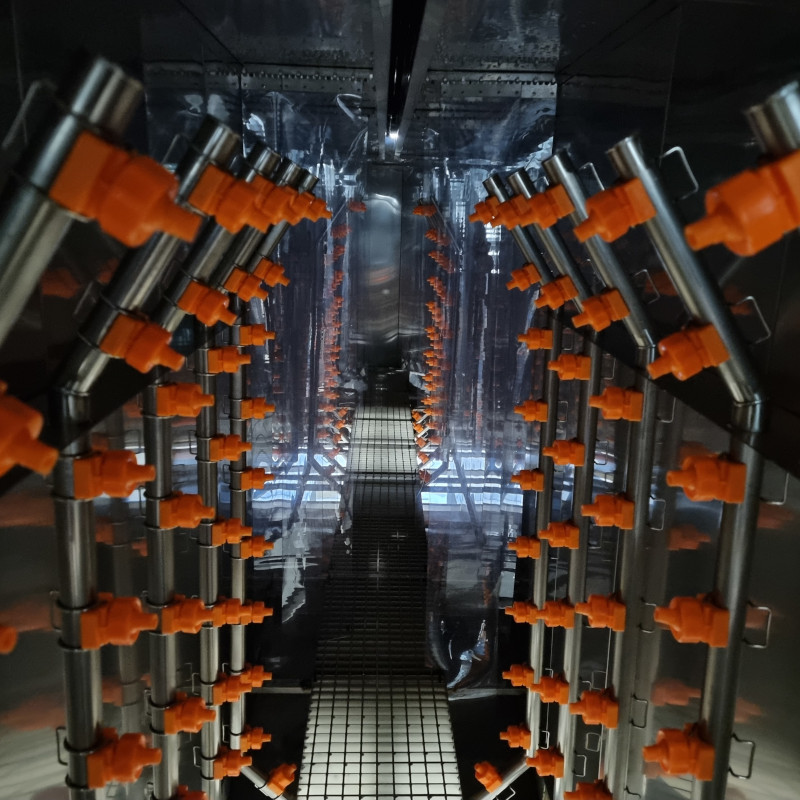

MTS is a system of many sensors located in extreme places of the chamber.

Paint polymerization at 180 degrees Celsius

|

ROMER

|

Other |

|

|

|

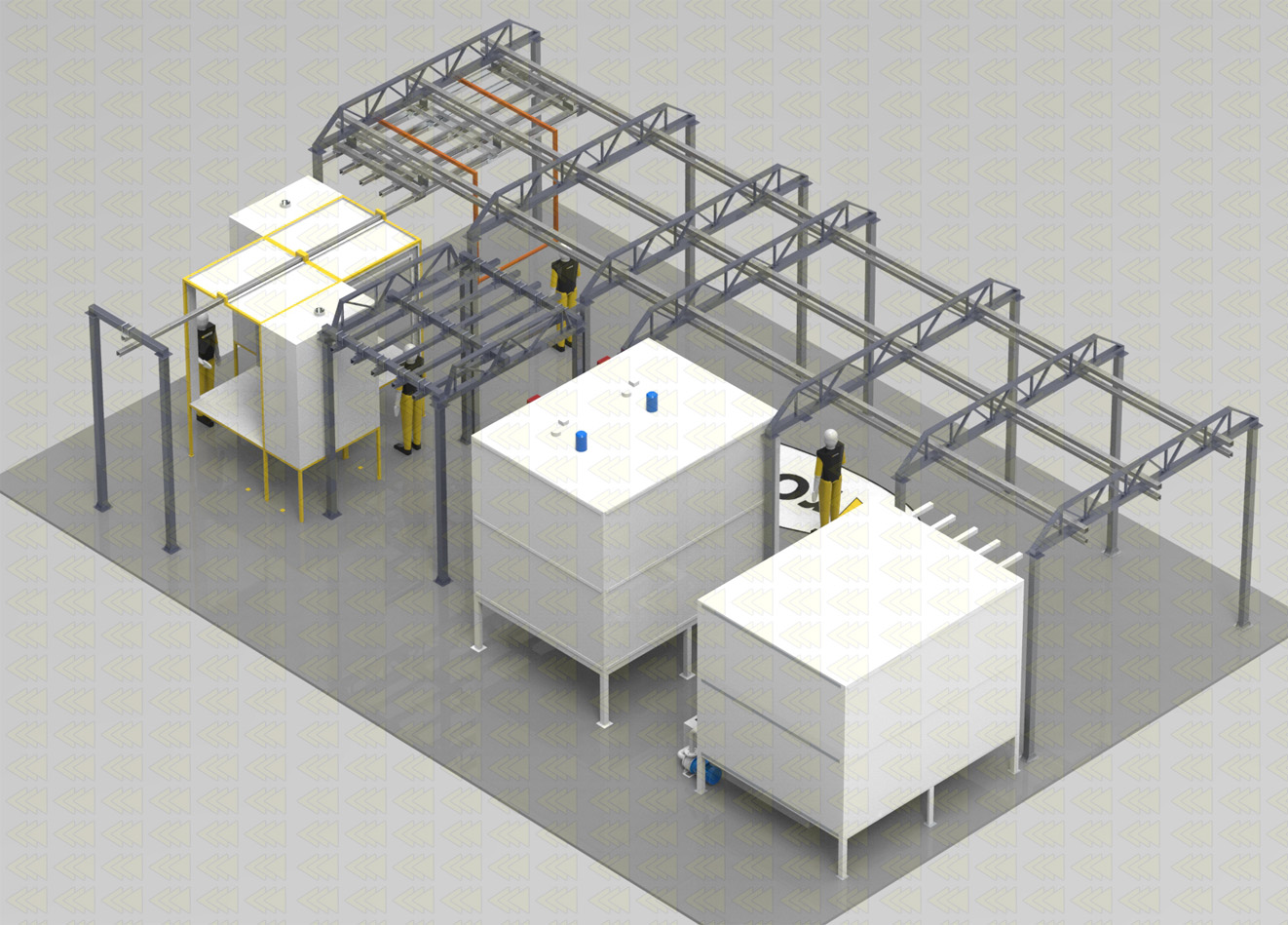

Heat & Cool

Heat & Cool

What are the Heat & Cool functions?

Our furnaces are equipped with functions that enable the determination of temperature increase or reduction over time with an accuracy of 0.01°C/min. The furnaces also allow you to set a temperature schedule according to predefined steps.

iCure recorder

software ROMER iCure

|

|

software ROMER iCure

|

|

Monthly capacity rollups |

|

Security

You can feel safe with us

|

Explosion proof closures |

|

|

|

|

|

|

Self-diagnosis The self-diagnosis system analyzes the correct operation of each component, preventing failures. |

Emergency cycle restart after power loss You ran out of electricity. What happens if you don't have this system, and you don't remember what stage the cycle was at? Entire load to improve. |

Analysis of connections correctness If you loose a plug, the sensors will be swapped, you can be sure that you won't have to think about it. |

|

|

|

|

Explosion-proof expansion damper In the event of fuel detonation in the combustion chamber, an additional adjustable flap has been provided which will then open preventing the explosion. |

Overheat sensor An additional sensor is activated when the upper temperature limit is exceeded, disconnecting the heating elements preventing damage to the elements. |

Securing directions of rotation In case of changing the phase sequence on the power supply, we have a protection that verifies it. |

Industry 4.0

Solutions that allow you to create your own extensive systems

|

Programmable outputs It allows you to add, for example, a controllable vacuum pump to the production process of carbon fiber elements, based on the achievement of a given temperature, heating / cooling curves, etc. |

|

RS485 ModBus communication |

|

Process view

Solutions tailored to your needs

|

Glass in the wall This allows you to view the annealed details from a close distance, especially when required by the process. |

|

Furnace lighting

|

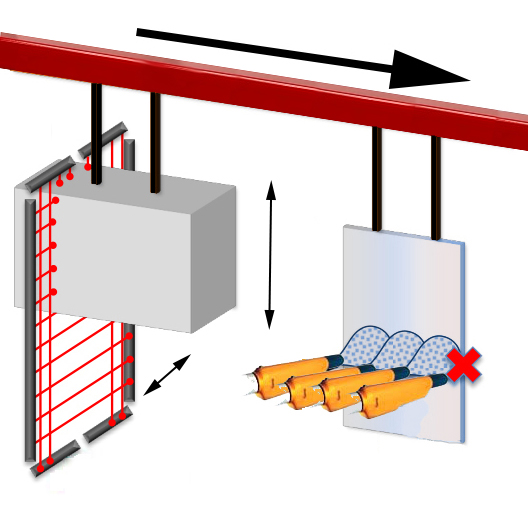

VFD system

So that the paint does not migrate after the oven

VFD system

What is a VFD system?

The VFD system was created to reduce the effect of paint migration after the oven

The standard solution is based on a system in which the fan always rotates at the same speed.

VFD is a system in which the fan speed is regulated by adjusting the frequency of the voltage waveform while maintaining the torque of the drive motor.

Depending on the stage of paint burning, the revolutions are adjusted to the set ones - minimizing the effect of paint migration after the furnace, and accelerating the heating of details in the dryer.

|

ROMER

|

Other |

|

|

|

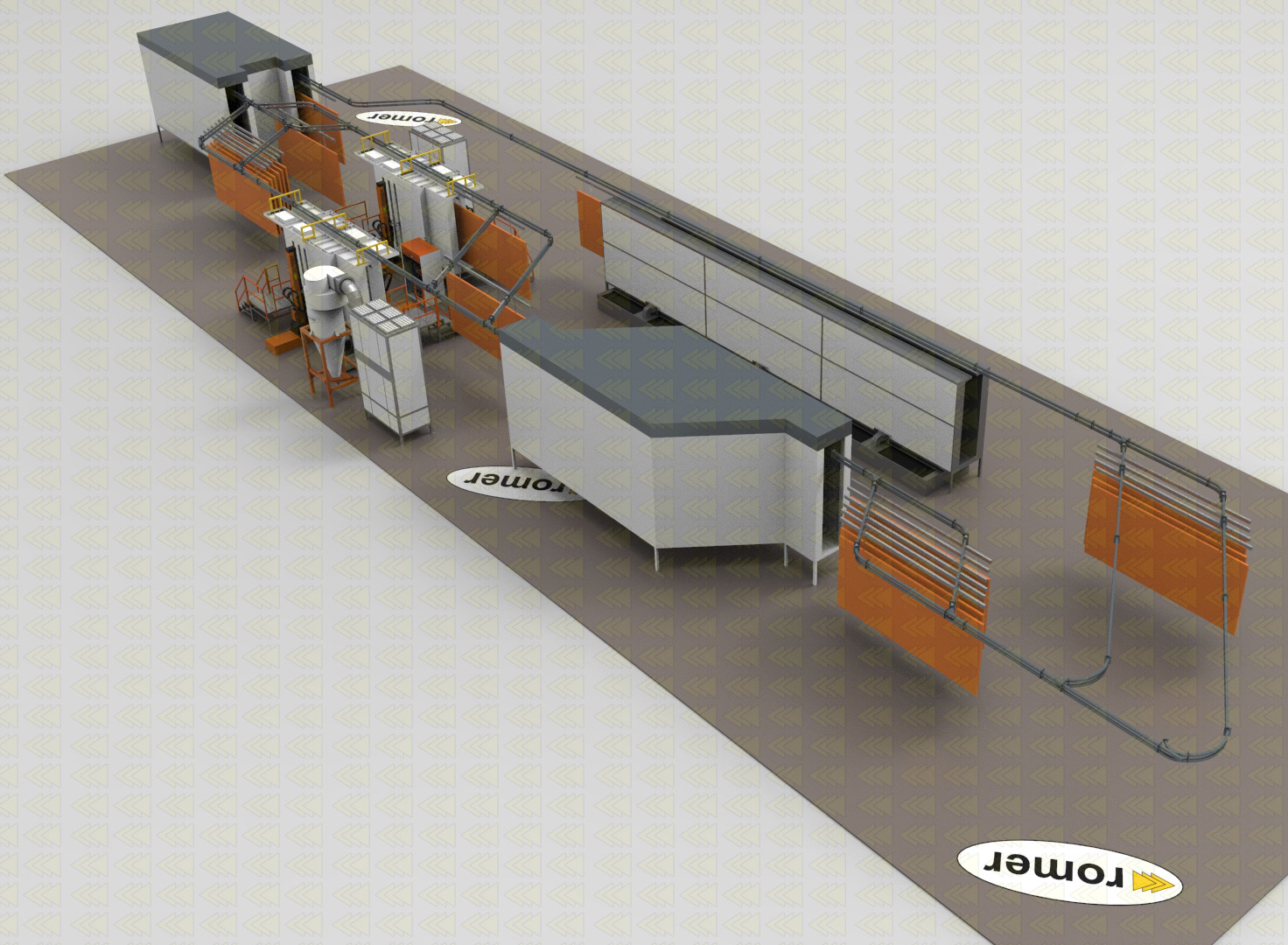

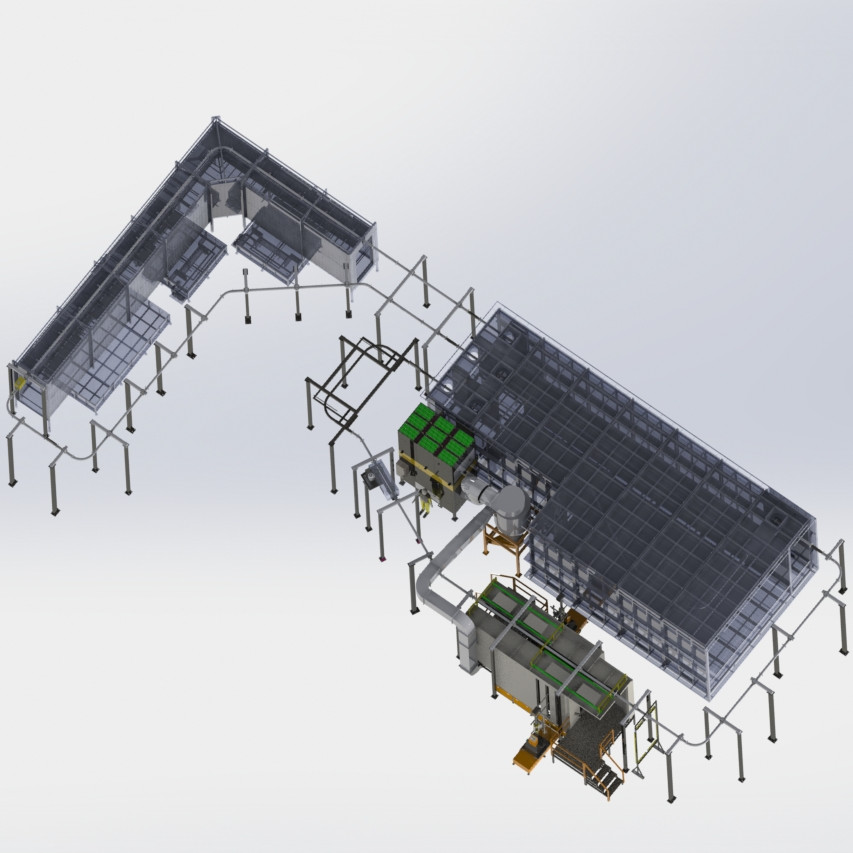

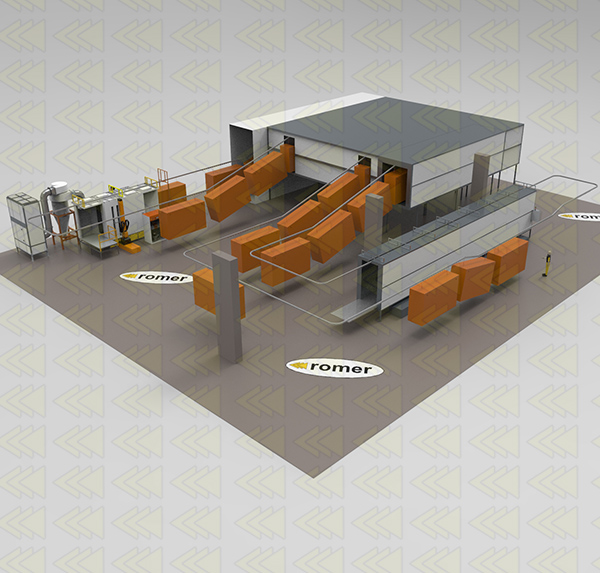

Transport methods

|

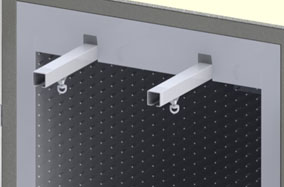

x

Upper tracks xOption with two trolleys, the most popular. Outdoor trolley equipped with swivel rubber wheels. The system is used for small and medium loads. It reduces the content of impurities from the floor in the chamber. The outer trolley is painted with wet paint, the inner trolley is moved on this trolley. Inner carriage delivered as a frame with high temperature bearings on rolling wheels, unpainted ready to weld the superstructure |

x

|

x

Rails in the floor x Option with two galvanized rails 70x70x4. The system is used for medium and heavy loads in large lines. This solution allows for one-time suspension of the element on the line, and then only moving it. Bottom carts |

x

x

x |

x

x x Option with one carriage, used for very heavy loads of several tons. The trolley is equipped with cast iron wheels on plain bearings. It prevents turning, the stroller only moves backwards and forwards. This option lowers the overall height of the stove by 100mm compared to the others. The trolley is delivered in the form of a frame with wheels. without superstructure, unpainted ready for welding. |

x

x

xx

xx

x